Our Featured Products

Find an extensive range of high-quality PU Industry products starting from raw material to finished products; Selected, Manufactured and Supplied by the experts in PU domain from all over the globe at the most competitive prices.

23 Density Industrial Flexible Foam

23 Density Industrial Flexible Foam

23 Density Industrial Flexible Foam

23 Density Industrial Flexible Foam23 Density Industrial Flexible Foam

At Foamvilla, we manufacture and supply 23 Density Industrial Flexible Foam, engineered specifically for applications where cost efficiency, moderate durability, and functional performance are the primary requirements.

These industrial-grade foams are formulated by blending high-quality Calcium Carbonate (CaCO₃) and other fillers with flexible foam raw materials, allowing us to produce an economical foam suitable for products that are designed to last for short to medium service life.This makes it a preferred choice for manufacturers targeting value-driven markets.

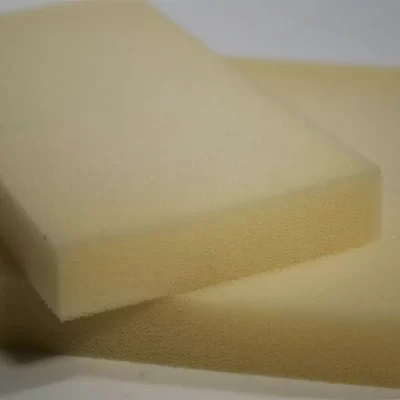

Quick Dry Memory Foam

Quick Dry Memory FoamProduct Code: FV-Memory-Quick Dry

We process Open-Cell, Quick-Dry Memory Foam for applications where rapid drying, cushioning, support, resilience, and slow recovery properties are required. As the name suggests, this foam features a fully open-cell structure that allows excellent air and water flow, enabling moisture to pass through easily.This ensures the foam dries significantly faster than conventional memory foams, preventing water retention and helping maintain hygiene and durability.

Because of its quick-drying capability, this foam is ideal for applications where the material comes in frequent contact with water, such as bath mats and outdoor furniture.Engineered for demanding environments, open-cell quick-dry memory foam retains all the essential qualities of viscoelastic foam—body contouring, pressure relief, and slow recovery—while offering superior breathability and drainage.

Pocket Spring Mattress

Pocket Spring MattressProduct Code: FV-Mattress-PSM

Our Pocket Spring Mattress is expertly designed to deliver a tailored sleep experience, combining comfort, support, and durability. Unlike traditional spring mattresses, each coil in a pocket spring mattress is individually encased in a fabric pocket, allowing independent movement of the springs. This design ensures that the mattress conforms precisely to the sleeper’s body, providing targeted support where it is needed most.The individual coil mechanism reduces motion transfer, making it an excellent choice for couples.

When one person moves or changes position, the other remains undisturbed, ensuring uninterrupted, restful sleep. The targeted support offered by the independent springs also helps alleviate pressure points on the shoulders, hips, and back, promoting proper spinal alignment and enhancing overall sleep quality.The open spring structure of our pocket spring mattresses ensures excellent air circulation, regulating temperature and preventing heat buildup.

Seat Covers Foam

Seat Covers FoamPolyurethane (PU) foam is a vital material in automotive seat cover systems, serving as the cushioning layer beneath upholstery fabrics. Its versatility, comfort, and durability make it indispensable for enhancing the seating experience in vehicles, whether for daily commutes, long drives, or luxury applications.

Key Applications and Benefits of PU Foam in Automotive Seat Covers

- Cushioning Layer: PU foam acts as the primary padding beneath seat covers, absorbing pressure and providing a comfortable seating surface for drivers and passengers.

- Ergonomic Support: By adjusting foam density and firmness, manufacturers can target support to specific body zones, including lumbar, thigh, and back areas, promoting proper posture and reducing fatigue.

15 Density Glue Lamination Foam

15 Density Glue Lamination Foam

15 Density Glue Lamination Foam

15 Density Glue Lamination FoamProduct Code: FV-In Rolls-15G

15 Density Glue Lamination Polyether Foam is a low-density foam specifically designed for economical glue lamination applications. Supplied in roll form, it can be customized in thickness, width, and color according to customer specifications and end-application requirements. Its lightweight composition makes it ideal for manufacturers aiming to produce cost-effective laminated products while maintaining consistent performance and quality.

Enhanced with quality additives, this foam provides superior glue lamination properties, ensuring excellent adhesion and durability across laminated surfaces. It is well-suited for single-side, double-side, and multilayer glue lamination machines, making it a versatile solution for a wide range of industrial and comfort-oriented applications.

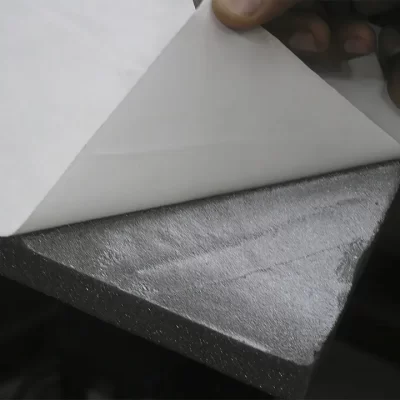

Self Adhesive Backing Acoustic Foam

Self Adhesive Backing Acoustic Foam

Self Adhesive Backing Acoustic Foam

Self Adhesive Backing Acoustic FoamProduct Code: FV-Acoustics-SAF

We offer Self-Adhesive Acoustic Foam Sheets in a wide variety of shapes, sizes, and colors, tailored to meet diverse industrial, commercial, and residential acoustic applications. These foams are available in both fire-retardant and non-fire-retardant grades, providing flexible solutions to meet safety requirements and regulatory standards.

Made from open-cell flexible polyurethane, these acoustic foams are specifically designed to maximize sound absorption and optimize acoustic performance. The open-cell structure allows sound waves to penetrate the foam, converting sound energy into thermal energy, which significantly reduces noise, reverberation, and echo.The availability of different profiles and shapes, including pyramids, wedges, and egg crate designs, further enhances the foam’s effectiveness by increasing the surface area and improving sound diffusion.

High Resilience Foam

High Resilience FoamProduct Code: FV-Resilience

High Resilience (HR) Flexible Foam is a premium polyether-based polyurethane foam designed to deliver superior comfort, support, and durability compared to standard foams. Known for its enhanced resilience properties, HR foam features an open, less uniform cell structure that allows it to quickly rebound after compression, closely mimicking the feel and performance of natural latex.

This makes it ideal for applications requiring repeated use and consistent comfort, such as high-end mattresses, sofas, upholstered furniture, and sofa seats, where it is often combined with viscoelastic (memory) foam to provide a firmer supportive base.

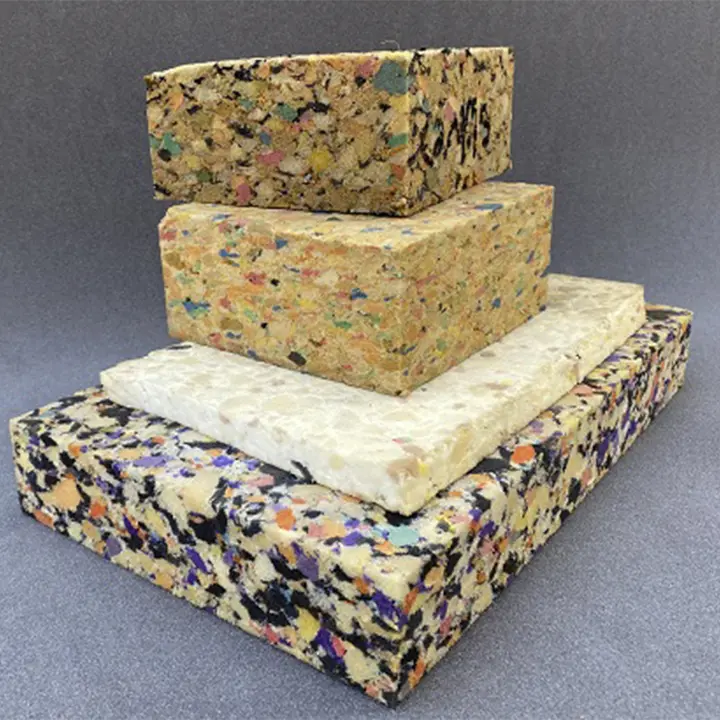

100 to 150 Density Rebounded Foam

100 to 150 Density Rebounded Foam

100 to 150 Density Rebounded Foam

100 to 150 Density Rebounded FoamProduct Code: FV-Recycled-100

At Foamvilla, we specialize in manufacturing and supplying high-density Rebonded Foam Blocks ranging from 100 to 150 Kg/m³, designed for industrial and commercial applications that require superior resilience, high impact resistance, and long-lasting durability. Our rebonded foam is produced by combining shredded foam chips with a specially formulated adhesive, which is then compressed and steam-cured to achieve precise density, hardness, flexibility, and rebound properties.

These high-density foam blocks provide excellent firmness and structural support, while offering a cost-effective alternative to pure-grade foam of similar density.Foamvilla can produce blocks in single-color batches using chips of the same color and in a variety of sizes to suit customized market or production requirements. Many B2B clients purchase these blocks in bulk and cut them into sheets of required thicknesses and dimensions, allowing flexible inventory management and quick adaptation to changing market demands without the risk of ordering incorrect sizes.